The next steps are to assess the surfaces of the samples

through micro indentation and profiling tests. These tests will allow for the

observation of the change in wear and friction of the surfaces as well as the

Young’s Modulus of the samples. Given if time permits mechanical and

tribological evaluations will be done on the ABS samples to observe the change

in mechanical strength and serve as another method of observing the surface

topography of the samples.This has been a rather

engaging experience that has allowed me to pursue my interest in the naval engineering

field. Furthermore, working with Dr. Beheshti has allowed me to gather a sense

of the lab working environment and has compelled me to develop my understanding

of the 3D printing process and corrosive behavior of the ocean through

whichever future opportunities may be presented.

Sunday, July 10, 2022

URSP Student Daniel Hernandez Analyzes the Surface Degradation of Additively Manufactured (AM) ABS Polymers for Naval Application

My name is Daniel

Hernandez, I am a junior at George Mason University working with Dr. Ali

Beheshti to analyze the surface degradation of additively manufactured (AM) ABS

polymers for naval application. This project is a continuation of my work done

in the summer semester to determine the viability of AM ABS polymers in a

saline environment in comparison to their traditionally manufactured

counterpart. Where the main focus this semester has been the aging of the ABS

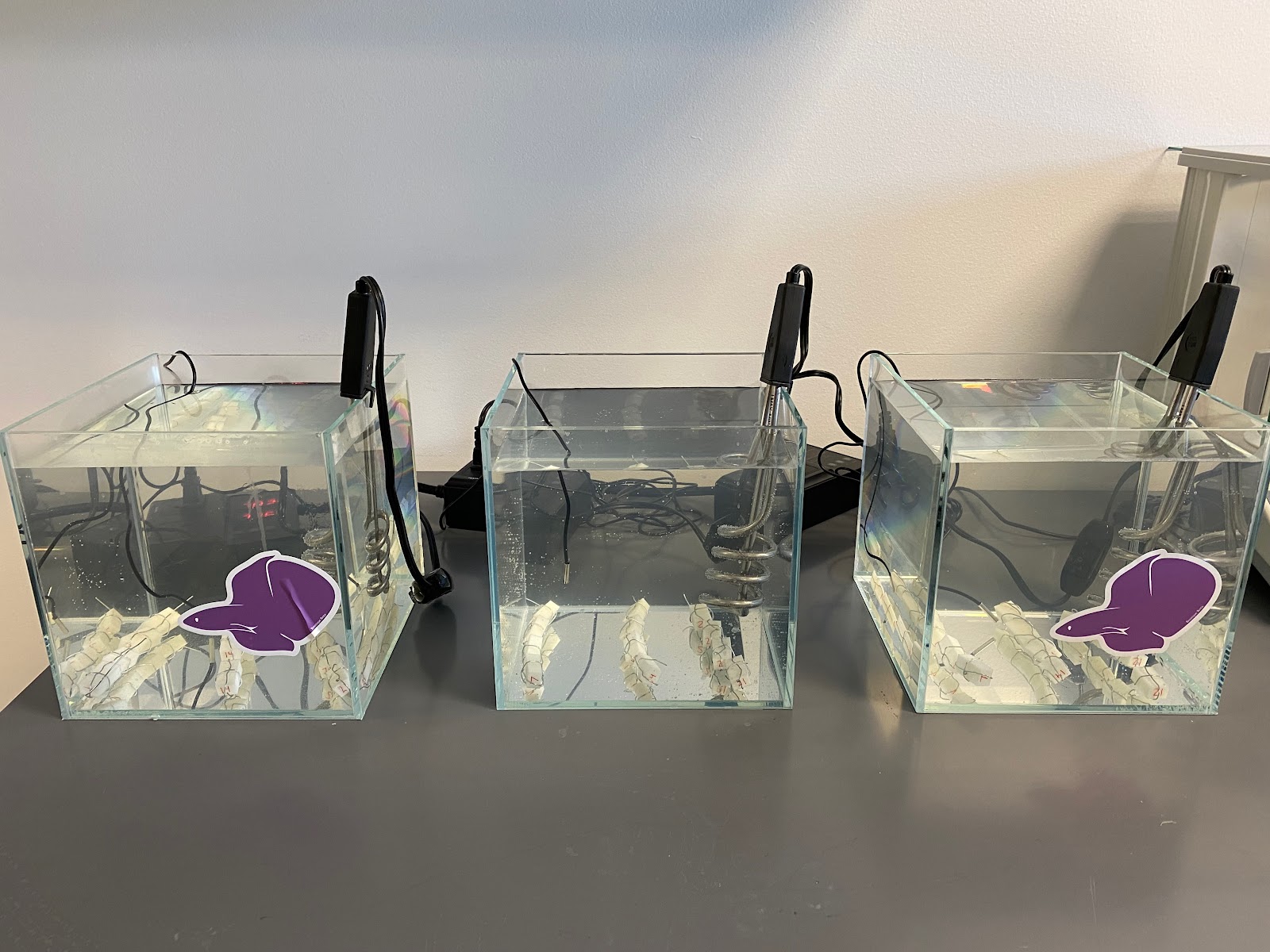

samples and observing the changes in the surface topography. The aging chambers

consisted of tanks filled with artificial seawater heated to 22°C, 27°C, and

105°C accordingly using a water heater with set submerged durations of 7, 14,

and 21 days. My day-to-day interactions consist of ensuring the proper levels

of seawater in the tanks and recording the change in mass of the samples.

Currently, only half of the samples have been aged though the remainder is set

to be finished soon.